Turnkey, sovereign, fully moulded plastic packaging.

We manufacture with extreme precision, using our highly automated microelectronic assembly process. Our manufacturing teams thrive on challenging projects where the solutions we produce push the boundaries of RF electronics and materials.

Fully moulded high-reliability plastic packaging

Packaged solutions for optimal Size, Weight and Power (SWaP)

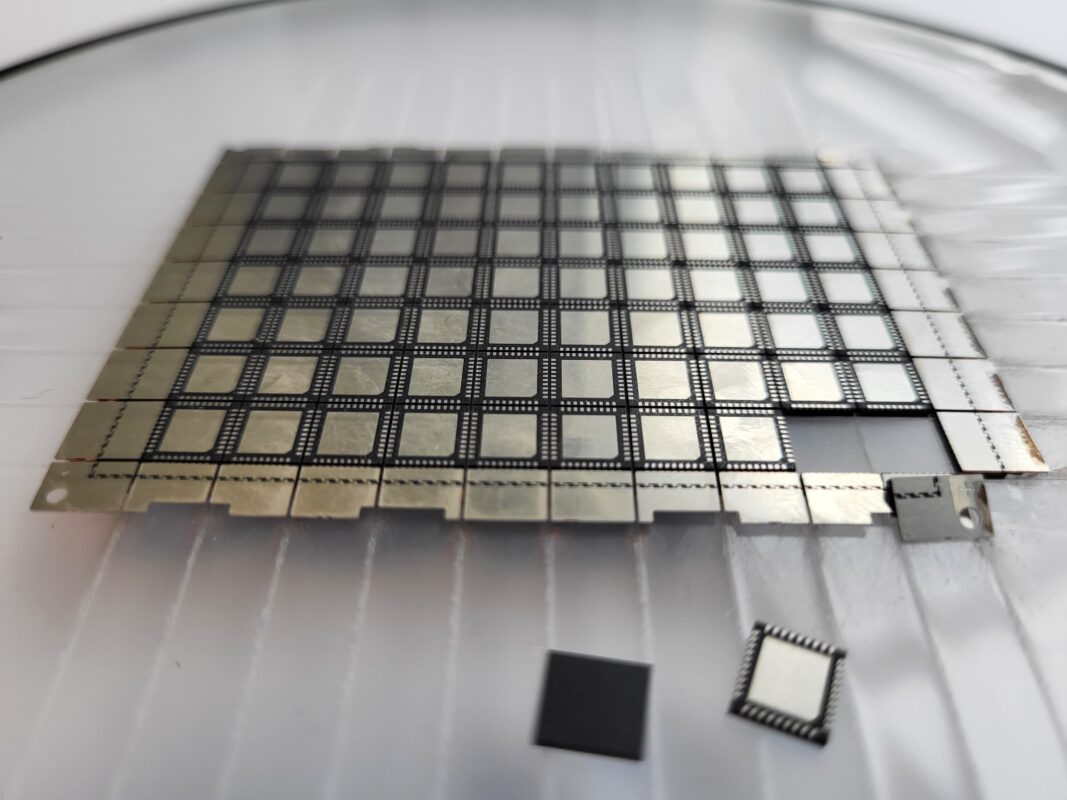

Filtronic invested in a specialist, plastic encapsulation capability for compound semiconductor devices, focusing on high-density System in Package (“SiP”) designs. Perfect for wideband gap semiconductors such as such as Gallium Arsenide (GaAs), Gallium Nitride (GaN), and Silicon Carbide (SiC).

We also offer extensive volume experience to customise and adapt products, optimising them for cost-efficient volume manufacture. With our significant investment in hybrid assembly, advanced microwave test systems, military standard processes and full traceability, we offer a unique low risk and secure service.

Process optimisation for high-reliability plastic packaging

Our capabilities focus on low-weight, low-cost, high-density packaging for high-power semiconductor devices, specifically designed to perform in challenging operational environments for the MoD, Royal Navy, Royal Air Force, and their global allies.

Our lead frame technology utilises best practices to mitigate delamination, voiding, improved solderability and wire bonding.

Watch our video to find out more about our manufacturing capabilities.

Features include

- Able to work on UK government contracts.

- Custom lead frame and package design capability to optimise electrical performance.

- Vertically integrated process development, manufacture, and test, all on one site, critical for security, continuous monitoring and improvements.

- Full in-house automated process capability. From Die Attach to Wire Bonding, Moulding, Dicing and Testing.

- Electrical test – DC & RF test.

- Open tooling or customisable lead-frames.

- Production and prototype volumes available

- RF and microwave package modeling for optimised performance.

- Dedicated process improvement, focusing on quality and optimising yield.

- Environmental qualification

Thermal analysis

Filtronic can provide full thermal analysis which is critical in selecting the correct die attach material, interconnect, and mould compound for the package design. Our expertise covers CTE mismatch and voiding.

Our end-end process includes a range of die-attach materials and interposers.

Capability to support volume production with full traceability of wafer and assembly lots.

Featured products

Morpheus II

Morpheus X2

Taurus

Related media

Popular news, articles and white papers

- Pushing the boundaries in LEO applications – Filtronic expands presence in satellite communications market

- Filtronic cements position in LEO market with a new follow-on contract for Cerus 32

- Filtronic awarded £4.5 million contract with BAE Systems

- Filtronic wins a new radar contract from Defence Prime

- Filtronic releases highest power (>20W), commercially available E-band solid-state power amplifier (SSPA) on the market

- Filtronic strengthens its position within the E-band low Earth orbit market with second-generation Cerus 32 power module

- Filtronic launches into the future, securing a Strategic Partnership with SpaceX for Starlink constellation

- Filtronic wins “Manufacturer of the Year” at the prestigious annual Elektra Awards

- UK RF manufacturer contributes to ‘fibre-in-the-sky’ low Earth orbit network

- Hercules takes off in markets with a need for speed.

- Filtronic win major contract with European Space Agency’s ARTES programme.

- Filtronic secures second ESA project in six months.

- Scaling up semiconductor manufacturing for new-space applications

- RF specialist selected for Defence Technology Exploitation Programme.

- A close shave: 5G to the rescue

- Filtronic strengthens sales partner network

- Filtronic wins the Innovative Supplier Collaboration Award by Leonardo

- RF technology leader adds new service to portfolio

- Designing for the future

- The RF spectrum is not infinite – Ensuring RF spectrum sustainability amidst soaring demand