Process control - Flexible, reliable, secure, scalable with full traceability

Process control management (MaRS)

Filtronic developed its custom MES system (MaRS) to track and document the transformation of raw materials to finished goods. MaRs provides Filtronic with full track and traceability of all components, end-to-end lot traceability from raw materials to finished goods in the field. At an individual and batch level, Filtronic can identify if there is a problem in one of the groups, lot traceability makes identifying the problem lot significantly smoother. Inventory control processes are tighter and transparent.

An overview of MaRS features:

- Manufacturing control system from shop floor release to dispatch

- Absolute process control

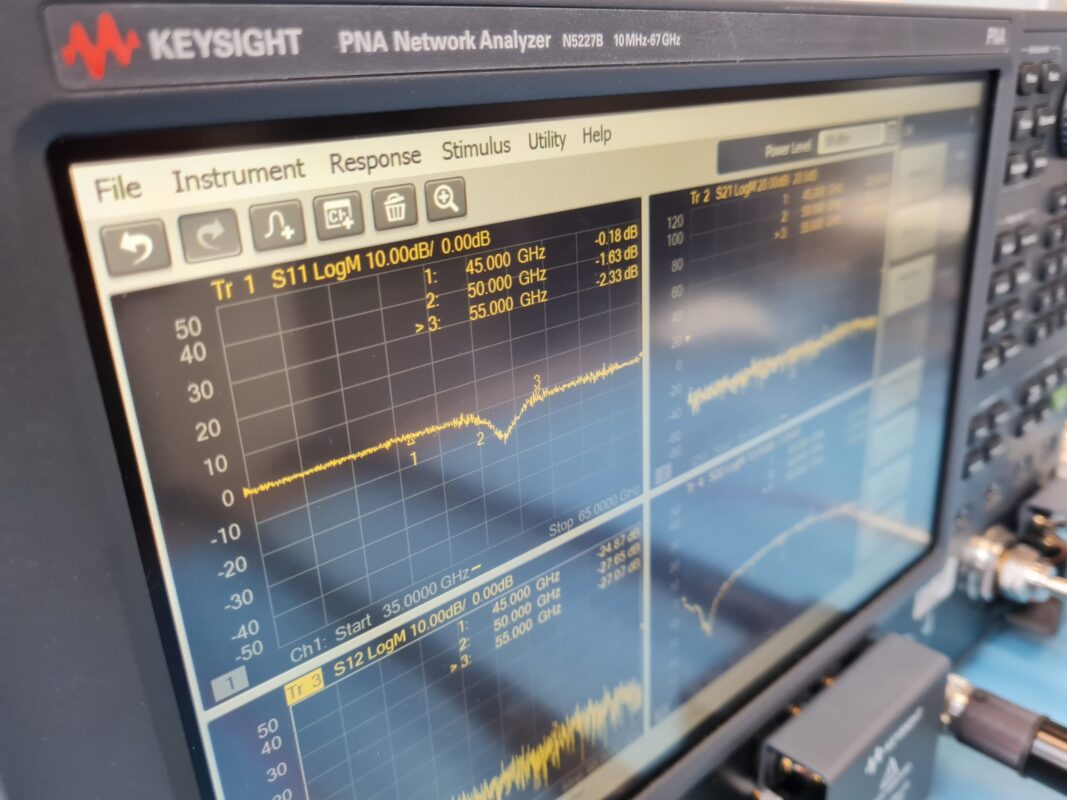

- Equipment control including automated control of test equipment, fully automated testing, calibration control and unit identification validation.

- Personnel control ensuring all operators are uniquely ID’d and only trained operators can run specific sequences.

- Material control

- Quality control

- Logisitics control

- Real time reporting

- Yield analysis

Fully integrated solution

Key features include:

- Serial number management

- Automated test environment

- Production floor control

- Live process monitoring

- Product labeling

- Tracks product build and history

- Production reporting

- Returns management

- Dispatch

- Tight version control and approval of processes

- Multiple environments and workflows for qualification testing

Our industry leading MES enables Filtronic to be agile, it is a highly reliable cloud based manufacturing execution system.

Related media

Popular news, articles and white papers

- Pushing the boundaries in LEO applications – Filtronic expands presence in satellite communications market

- Filtronic launches into the future, securing a Strategic Partnership with SpaceX for Starlink constellation

- Filtronic cements position in LEO market with a new follow-on contract for Cerus 32

- Filtronic awarded £4.5 million contract with BAE Systems

- Filtronic wins a new radar contract from Defence Prime

- Filtronic releases highest power (>20W), commercially available E-band solid-state power amplifier (SSPA) on the market

- Filtronic strengthens its position within the E-band low Earth orbit market with second-generation Cerus 32 power module

- Filtronic secures $9 Million order to boost SpaceX’s Starlink deployment with advanced E-band SSPAs

- Unveiling the future of E-band

- Filtronic ushers in new leadership era with CEO Nat Edington

- UK RF manufacturer contributes to ‘fibre-in-the-sky’ low Earth orbit network

- Filtronic wins “Manufacturer of the Year” at the prestigious annual Elektra Awards

- Hercules takes off in markets with a need for speed.

- Filtronic win major contract with European Space Agency’s ARTES programme.

- Filtronic secures second ESA project in six months.

- Scaling up semiconductor manufacturing for new-space applications

- A close shave: 5G to the rescue

- RF specialist selected for Defence Technology Exploitation Programme.

- Designing for the future

- The RF spectrum is not infinite – Ensuring RF spectrum sustainability amidst soaring demand