Technology leaders across the Microwave spectrum

Prototype characterisation and volume testing

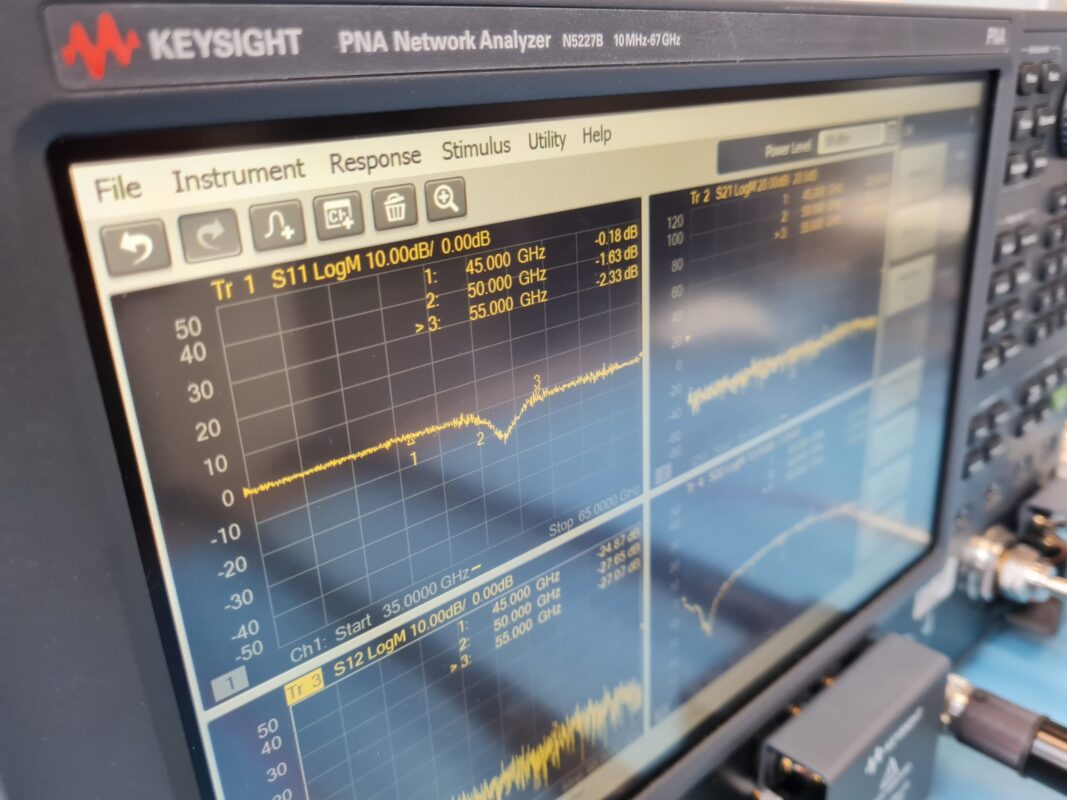

Uniquely, manufacturing and testing of our products occurs in-house at our state-of-the-art high volume manufacturing facilities. This enables us to develop tailored, rigorous, robust testing at every stage of production, which may include:

Sedgefield capabilities include:

- Electrical testing DC to 114GHz

- Environmental & stress screening

- 100% electrical characterisation over full operating temperatures

- Destructive and non-destructive tests

- Die level MMIC wafer acceptance testing and characterisation

- Pre and post-lid tests

- Module calibration

- Fully automated software controlled volume testing

World leading process control and full traceability

Enabling clients to take advantage of our industry leading manufacturing processes and test facilities. We help our clients to remove cost from their operations, reducing their labour costs, improving their processes by removing waste. We also reduce time to market, giving our clients the flexibility to ramp up and down rapidly, improving quality all without any additional overheads or purchasing capital equipment.

Our robust web-based manufacturing and process control system ensures real-time organisation wide access to material traceability, inventory management, WIP tracking, SPC, yield reporting and on-time delivery.

All components are tracked via a unique serial number ID providing full end-to-end process control. They uniquely identified each operator, ensuring complete user monitoring and enabling role-based authorisation to allow only trained operators to run specific workflow sequences.

Test solutions – smart support software “FIDO”

Proprietary smart support software “FIDO” interrogates the WATS database and our proprietary inhouse (WIP tracking) system.

- If certain tests fail within specified parameters, they trigger FIDO

- FIDO interrogates the WATS and Felix databases and determines whether device under test (DUT) is likely to pass if module parameters are incrementally adjusted and DUT retested

- FIDO will either adjust variables within the product firmware or trigger a recalibration

- The module is then automatically retested

- Undertaken with no operator intervention in order drive efficiency

- FIDO clusters common test failure modes – providing efficient guidance for diagnostic technicians

Salisbury, USA

- PIM chamber for telecom device testing (700, 800, 900, 1900 & 2600 MHz)

- Network Analysis up to 8.5GHz

- Discrete Signal Analysis up to 18GHz, (Sig Gens, Spectrum Analyzers, Power meter)

- Noise Figure Analysis up to 3GHz

Leeds, UK

- Environmental stress testing with the latest temperature and humidity chambers

- Thermotron™ temperature and humidity chamber volume of 32ft3

- Test Equity™ temperature chamber volume of 27ft3

- Sun Systems™ temperature chamber volume of 2.2ft3

- RF analysis test equipment coupled with automated test software PIM chamber for telecom device testing (700, 800, 900, 1900 & 2600 MHz)

- Network Analysis up to 50GHz

- Discrete Signal Analysis up to 44GHz, (Spectrum Analyzers, Power meter)

- Noise Figure Analysis up to 18GHz

Manchester, UK

- Environmental stress testing with the latest temperature chambers

- Network analysis up to 50GHz

- Discrete Signal Analysis up to 50GHz, (Spectrum Analyzers, Power meter)

- Noise Figure Analysis up to 50GHz

Related media

Popular news, articles and white papers

- Pushing the boundaries in LEO applications – Filtronic expands presence in satellite communications market

- Filtronic launches into the future, securing a Strategic Partnership with SpaceX for Starlink constellation

- Filtronic cements position in LEO market with a new follow-on contract for Cerus 32

- Filtronic awarded £4.5 million contract with BAE Systems

- Filtronic wins a new radar contract from Defence Prime

- Filtronic releases highest power (>20W), commercially available E-band solid-state power amplifier (SSPA) on the market

- Filtronic strengthens its position within the E-band low Earth orbit market with second-generation Cerus 32 power module

- Filtronic secures $9 Million order to boost SpaceX’s Starlink deployment with advanced E-band SSPAs

- Unveiling the future of E-band

- Filtronic ushers in new leadership era with CEO Nat Edington

- UK RF manufacturer contributes to ‘fibre-in-the-sky’ low Earth orbit network

- Filtronic wins “Manufacturer of the Year” at the prestigious annual Elektra Awards

- Hercules takes off in markets with a need for speed.

- Filtronic win major contract with European Space Agency’s ARTES programme.

- Filtronic secures second ESA project in six months.

- Scaling up semiconductor manufacturing for new-space applications

- A close shave: 5G to the rescue

- RF specialist selected for Defence Technology Exploitation Programme.

- Designing for the future

- The RF spectrum is not infinite – Ensuring RF spectrum sustainability amidst soaring demand