How to accelerate product development for complex mmWave technologies in LEO satellite communications

How to accelerate product development for complex mmWave technologies in LEO satellite communications

Dan Rhodes, Director of Business Development, Filtronic

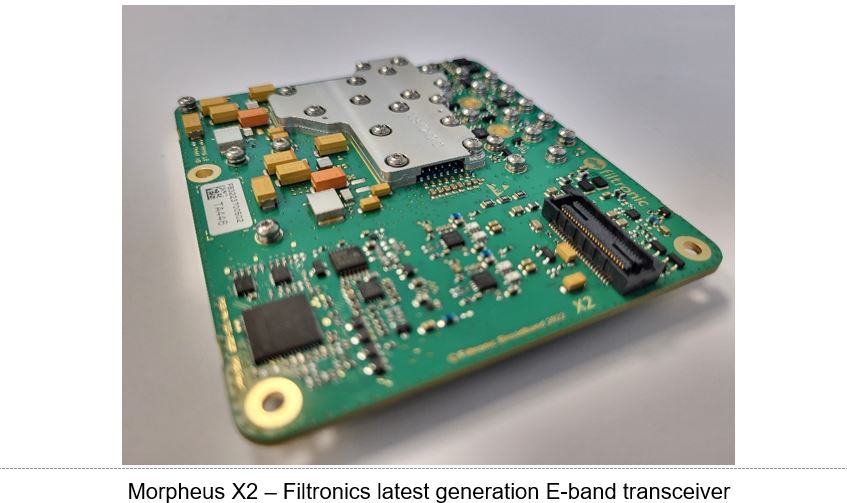

Over the past decade, Filtronic has achieved major advances in developing mmWave communications technology for challenging terrestrial applications. The core technology now employed within the latest iteration of its E-band transceiver (Morpheus II & Morpheus X2) and amplifier (Cerus) modules provide the basis for cost-effective, high-performance transceivers and amplifiers required for ultra-high-capacity satellite communications.

Core technology for LEO satellite communications

E-band transceivers and amplifiers are the essential components required by global communications businesses to support the planned development of mega satellite constellations in Low Earth Orbit (LEO). While these global organisations have considerable electronic engineering expertise and resources at their disposal, any in-house development programme cannot avoid the time, cost and pitfalls associated with complex E-band product development.

The core E-band technology developed by Filtronic over ten years of optimisation and innovation presents LEO satellite businesses with an opportunity to bypass these lengthy in-house development programmes – and potentially accelerate their satellite launch activities.

Innovations in E-band technology

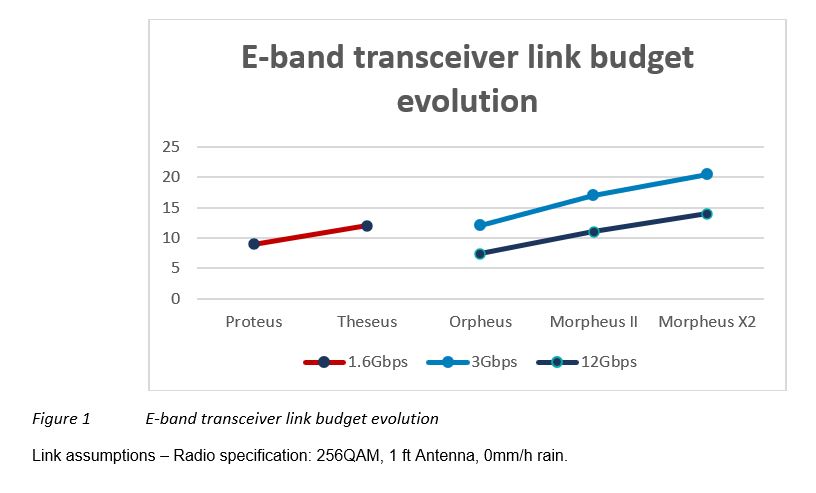

This paper provides a high-level outline of some of the key innovations made by Filtronic in its E-band technology, since it produced its first E-band transceiver – Proteus – ten years ago. These advances in the core transceiver and amplifier technology have reduced development time and materials costs, increased production volumes and improved manufacturing yields, while significantly enhancing the performance of these complex components. Below details each generation of E-band product and product launch date.

Any product development programme aims to achieve improvements in size, weight and power, and this has been a key focus in the development of E-band components at Filtronic.

The graph below demonstrates the increasing terrestrial link budget for each next-generation transceiver development, arising from the increasing transmit power and linearity performance. NB: these numbers are for terrestrial links only, ground to low earth orbit is available on request.

These improvements have been achieved principally through the following innovations:

1. Integration

The original Proteus transceiver contained separate radio frequency (RF) and control boards within the module. Through the development process, these two circuit boards have been combined into a single board. This brings with it several advantages, including reducing the size and weight of the product, reducing the number of parts, simplifying product assembly, and reducing material costs. Most importantly, greater integration within the circuit board improves the overall performance of the module, with RF bandwidths increased from 500MHz to >2GHz, reductions in receiver noise figure and reduced spurious products.

2. Component rationalisation and improvement

The receiver in the Morpheus II has been simplified. The Proteus module featured a dual stage downconverter including an IF stage, with a number of associated MMICs and filters in the receive chain. In Morpheus, these have been replaced with an LNA & direct downconverter, significantly reducing the component count (and therefore the potential for component failure), reducing manufacturing costs and at the same time improving performance.

Filtronic’s continued investment in in-house MMIC design brought new capabilities in power amplifier performance. Morpheus II incorporates our latest generation E-Band GaAs HPA (High Power Amplifier), which increased the linear operating point of our transceiver from 16dBm (Orpheus) to 21dBm Morpheus II, and 24dBm (Morpheus X2 – including diplexer losses), at the same time as reducing the overall size and weight of the product.

Unlike Proteus, Morpheus II does not require numerous mechanical protective covers over key electronic components. Fitting these mechanical covers at the micro scale of a transceiver module was a complex procedure, adding time to the assembly process. Morpheus reduced the number of bespoke metalwork components from 7 (including integrated diplexer) to just 2 (also including the diplexer). Reducing the metalwork component count simplifies and accelerates the production process, enabling costs to be reduced and output volumes to be increased.

3. Cost reduction

The development of Morpheus II has been an iterative process of design, testing and refinement to deliver incremental improvements at every stage. When Proteus was first developed, it was an entirely new product at the leading edge of mmWave innovation. Creating such a novel new product demanded considerable time and resources to make the progression from initial concept through to development and prototyping. Thanks to the lessons learned along the way and the efficiencies introduced at each stage, the development time for Morpheus II was significantly less than for Proteus. In fact, development costs for Morpheus II were less than a tenth of the same costs for Proteus.

What’s more, the simplification of components and reduction in the number of parts in each module means that the build costs per unit for each transceiver today are a third of the cost per unit of the original product.

4. Advances in manufacturing

Many of the advances in performance and cost are the result of design, integration and efficiency improvements. Further improvements in yields, accuracy and efficiency have been achieved thanks to investment in precision manufacturing and testing facilities, and the introduction of greater automation. As Filtronic has developed its in-house expertise in designing and manufacturing these complex components, it has been able to refine the manufacturing process and improve internal manufacturing yields.

This has enabled extremely complex components with intricate parts to be assembled with high degrees of accuracy, while improving operational efficiency and output. Ten years ago, Filtronic was producing 200 Proteus units per month, while today it can manufacture more than 3,000 Morpheus II transceivers in the same time. This considerable increase in output, combined with reductions in unit costs, equates to a significant financial saving per unit manufactured. It also enables Filtronic to meet our customers production ramp requirements successfully and consistently.

5. Accelerated testing

For such intricate and high-performance components as E-band transceivers and amplifiers, rigorous testing is required on every single unit. Batch testing is not sufficient to ensure that stringent quality standards are met in every module. This adds time to the production process. However, vast efficiency improvements have been made in testing, alongside the increases in production volumes. The time taken for testing, diagnostics and reworking for Proteus was over four times the length it takes for Morpheus II.

Versatile technology for space applications

It’s important to note that the core technology within Morpheus II and Cerus was developed for use in terrestrial applications. The terrestrial mobile communications market is highly cost-competitive, which means these are extremely lean products designed for optimum performance and efficient manufacture.

Crucially, for LEO satellite operators, these components are well suited to space applications. Filtronic mmWave products have been exhaustively tested, meaning they offer the proven reliability required. To date, we have shipped over 80k E and V-Band products. Additionally, they have the necessary high-performance levels for satellite systems, where performance is crucial and maintenance and repair are impossible. The compound semi-conductor (core MMIC line-up) technology used in Filtronic transceiver and amplifier modules is inherently radiation tolerant, making it fully compatible with space deployment. Other components, such as power supplies and micro-controllers, which feature silicon, are susceptible to radiation, but these can be replaced easily with readily available radiation-hardened alternatives.

The importance of design for manufacture

Key to the successful volume production of Morpheus II and Cerus is the fact that these products were specifically designed with precision manufacturing in mind. As a vertically integrated, multidisciplinary organisation, Filtronic has all the expertise in-house to enable the agile development of high-performance complex mmWave components for high-volume manufacturing.

The core skill base at Filtronic includes RF systems engineers, filter specialists, PCB layout designers, process engineers and software experts, to name a few. These specialists work collaboratively together, liaising with manufacturing planners, process management and testing specialists, to ensure the RF solutions developed are not only quality-assured and reliable, but can also be manufactured efficiently at scale.

When you’re dealing with such complex components, designing specifically for manufacture is essential. Problems often arise when the design process is divorced from the manufacturing operations. Filtronic has been called on many times to help improve components designed by clients in-house or by competitor organisations, which have proved inefficient to manufacture at scale. In one case, the client needed to improve yields for a V-band transceiver as production volumes were ramped up. Filtronic introduced a design for manufacture improvement, and took over the volume manufacturing operations, resulting in an increase in yield from 70% to more than 95%.

Pushing the boundaries

Filtronic has a long history of extending the possibilities of RF communications technology. Its track record of innovation means its expertise is frequently called upon by leading telecommunications, aerospace, defence, first-responder and space communications companies to expand the capabilities of communications systems.

As an example, one of the FAAMG technology giants challenged Filtronic to develop a transceiver for use in a new high-altitude pseudo-satellite (HAPS) application. The client wanted a transceiver that could achieve data rates of 40GB per second. At the time, the best solution available offered speeds of just 1GB per second. Such a vast improvement seemed unattainable, but Filtronic applied its ingenuity and electronic engineering skills to develop a transceiver that delivered exactly the 40GB speeds required by the client.

Opportunities to accelerate satellite communications development

In satellite communications technology, there’s no room for compromise on quality or rigour in the product development process. E-band components are required to perform reliably to extremely high standards in the harsh conditions of space – where the failure of any component comes at a high cost. There is no maintenance call-out service for orbiting satellites.

For those communications organisations competing to deliver aggressive satellite launch programmes, time saved in product development could be the key to getting ahead of the competition. The advances in E-band technology achieved by Filtronic, combined with its practical experience and expertise, could be the solution to expediting the development of vital mmWave communications systems for LEO satellites. Contact Filtronic today to find out how we can help accelerate your market entry.