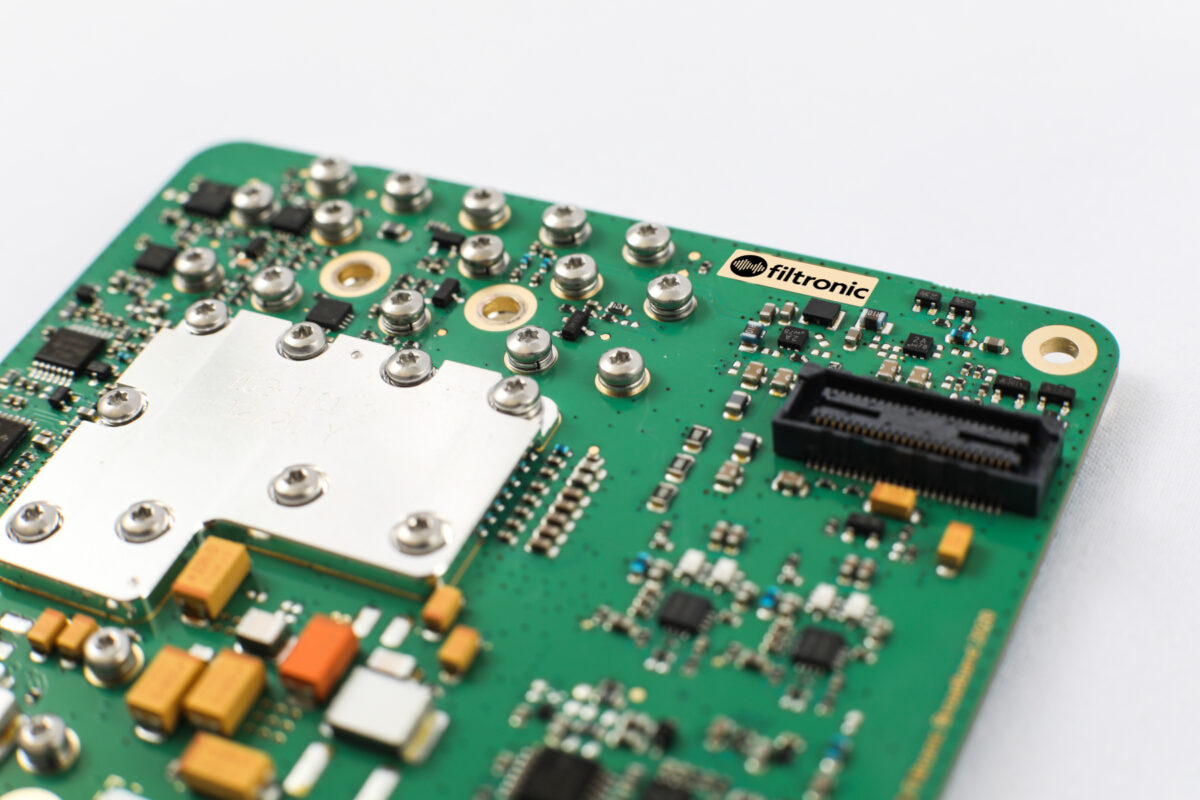

High-quality, cost-effective contract electronic manufacturing and assembly

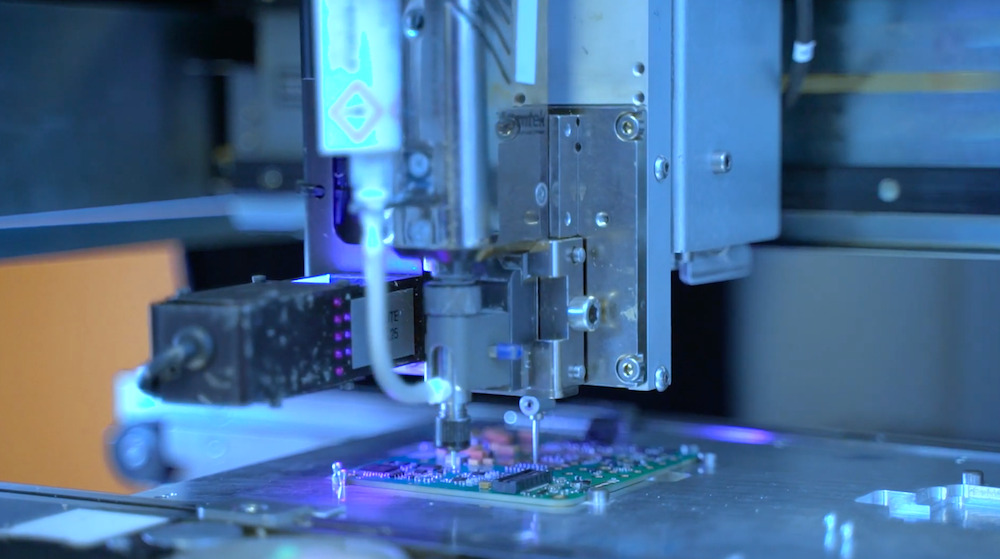

We manufacture with extreme precision, using our highly automated microelectronic assembly process. Our manufacturing teams thrive on challenging projects where the solutions we produce push the boundaries of RF electronics and materials.

Precision microelectronics manufacturing

Microelectronics manufacturing from our state of the art facilities, Filtronic specialises in the manufacture of active and passive RF solutions for critical communications. Using highly automated processes, our manufacturing teams thrive on challenging projects where the solutions we produce push the boundaries of RF electronics and materials.

Producing precision components and hybrids to client specifications in our 24-hour production facilities, we offer contract design and microelectronic manufacturing services in both the UK and USA. Providing services that add value, make clients’ lives easier, and allow them to increase sales. We offer a range of order-fulfilment options, such as manufacturing close to market, inventory hubbing and site-kitting.

We also offer extensive volume experience to customise and adapt products, optimising them for cost-efficient volume manufacture. With our significant investment in hybrid assembly, advanced microwave test systems, military standard processes and full traceability, we offer a unique low risk and secure service.

Hybrid manufacturing services

Our hybrid contract microelectronics manufacturing services enable customers to realise their own designs using Filtronic’s precision microelectronic facilities, supported by a strong operations and manufacturing engineering team. This enables cost-effective outsourced electronics manufacture and sustained cost reduction services for customers requiring complex and high mix products to high reliability and quality levels.

Watch our video to find out more about our manufacturing capabilities. We offer contract microelectronics manufacturing services in both the UK and USA, providing cost-effective manufacture in our 24-hour production facility for both volume and high mix products.

Our facilities

- NETPark, Sedgefield, UK

- 13,000 square feet total size

- 2,000 square feet ISO 8 clean rooms

- 2,000 square feet engineering laboratories

- 5,000 square feet of ESD safe work area for sensitive designs

- Salisbury, USA

- 16,000 square feet total size

- 20,000 square feet under temperature control

- 5,000 square feet of ESD safe work area for sensitive designs

Microelectronic manufacturing services (USA)

Filtronic offers competitive contract assembly and test services for a range of sectors including critical communications; telecom infrastructure and aerospace & defence from our Salisbury, Maryland site.

An overview of services include:

- Quick-turn electronics assembly

- Equipment build-up (including rack, stack and commissioning)

- Equipment and operational testing

- Repair depot with embedded process audit

Customised manufacturing solutions

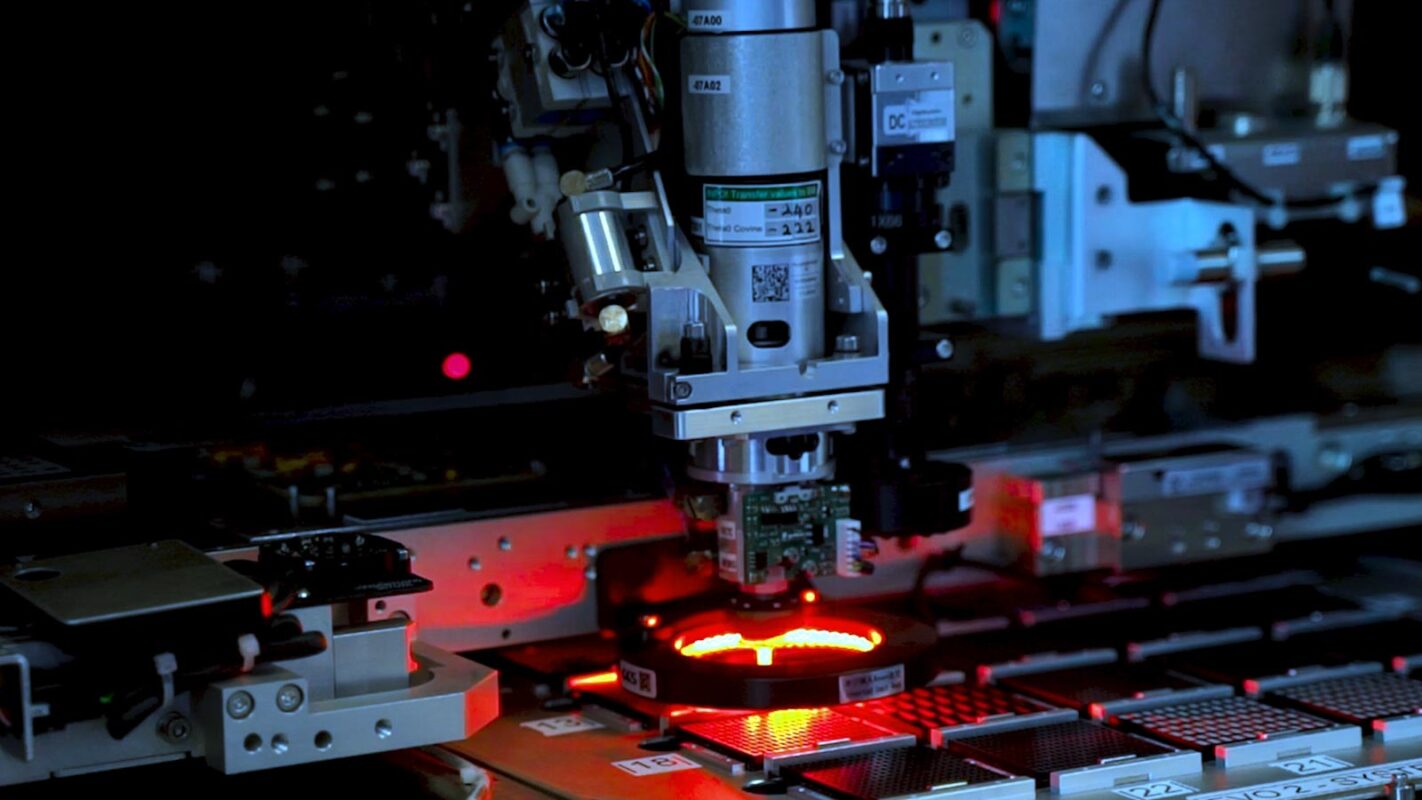

Fully automated front end assembly including epoxy and solder dispense, die and component attach technology, wire bonding (ball, wedge and ribbon). Additional facilities include air cavity packaging and hermetic sealing.

All processes are supported by our in-house leading manufacturing engineers and process engineering teams.

Powered by people

We have a wide range of skill sets including:

- RF system engineers

- MMIC specialists

- Filter specialists

- Electronic and PCB layout designers

- Mechanical design

- Process engineers

- Software and firmware experts

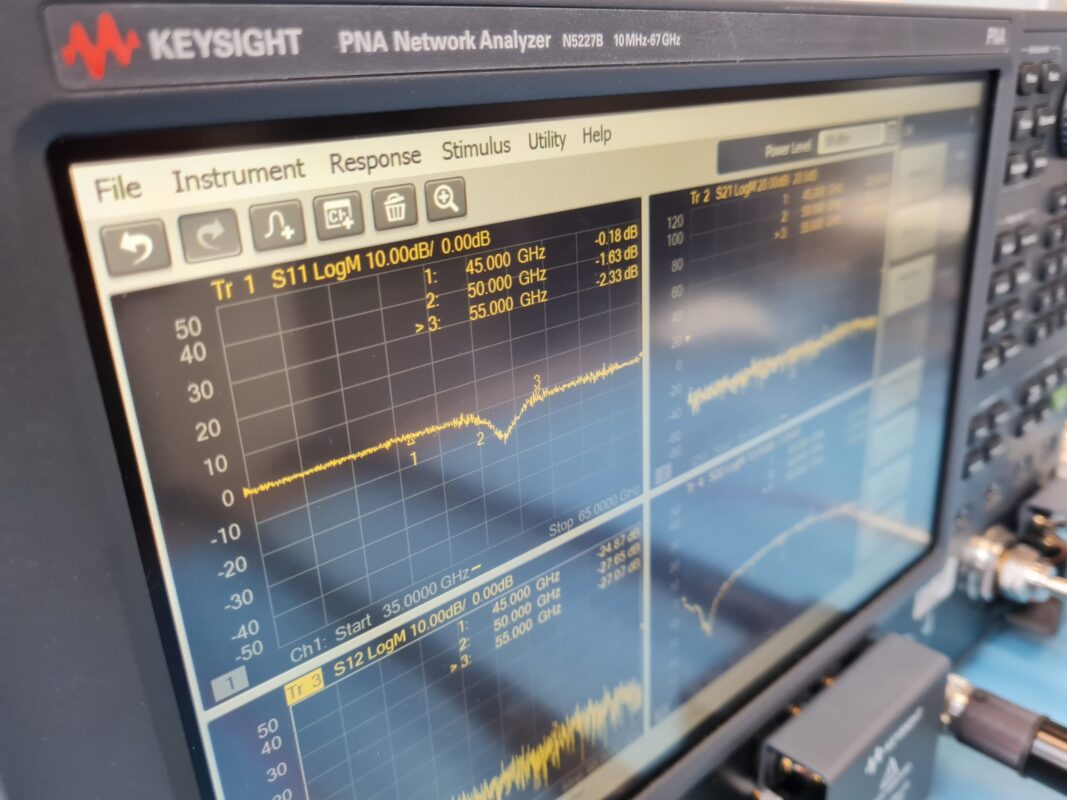

In-house testing for complete quality assurance

Uniquely, many of our products are manufactured and tested in-house at our state-of-the-art high-volume manufacturing facilities. This enables us to develop tailored, rigorous, robust testing at every stage of production.

Test facilities include:

- Electrical testing DC to >114GHz

- Environmental & stress screening

- 100% electrical characterisation over full operating temperatures

- Destructive and non-destructive tests

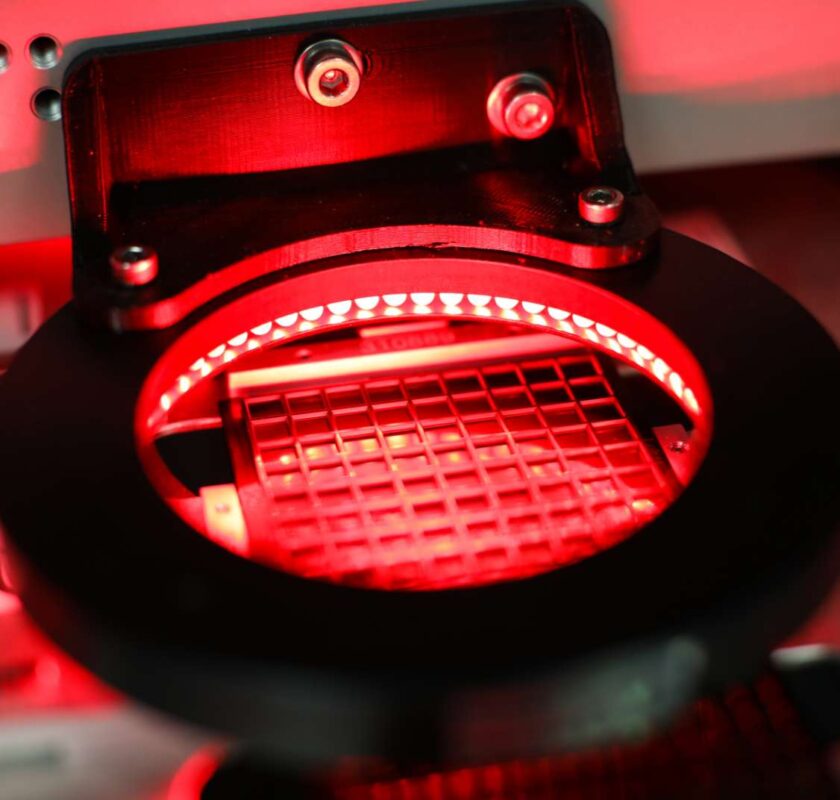

- Die level MMIC wafer acceptance testing and characterisation

- Pre and post-lid tests

- Module calibration

- Fully automated, software controlled volume testing

Process control for full traceability

Our robust proprietary microelectronic manufacturing and process control system ensures real-time organisation wide access to material traceability, inventory management, WIP tracking, SPC, yield reporting and on-time delivery.

Real time throughout and yield tracking

- Displays throughput and yield by process

- Can be filtered by Job, Product, Sequence, Site

- Displayed by Hour/Shift /Day /Week/Month

Control

- Define work flow.

- WIP track individual parts.

- Assemblies must progress through the defined process flow.

- Ensures operators are trained for processes.

- ESD controls are auto-enforced.

Detailed item status

- Parent/child assemblies and sub-assemblies have unique serial numbers for full material control and traceability.

Epoxy dispense and die attach

Fully automated epoxy dispense and component placement equipment provides tightly controlled, accurate and repeatable component attach.

- Deep access epoxy dispense capability

- Accuracy of 35um and repeatability of 15um

Die and component attach technology includes; Epoxy, Eutectic, Silver Sinter with an X/Y placement accuracy +/- 10 microns and the capability to pick from gel, waffle pack and reel.

Wire bonding

Filtronic’s fully automated wire bonding capabilities include wedge, ribbon and ball. Our team of highly trained and experienced wire bond operators ensure that all work is carried out to the highest standard. Robust & reliable wire bond process capabilities are developed by optimising and tightly controlling the key wire bond process and material parameters. Ball shear and wire pull test are used as tools to qualify and centre the process. Sample ball shear and pull test are then used during manufacture in order to maintain high levels of quality & yield

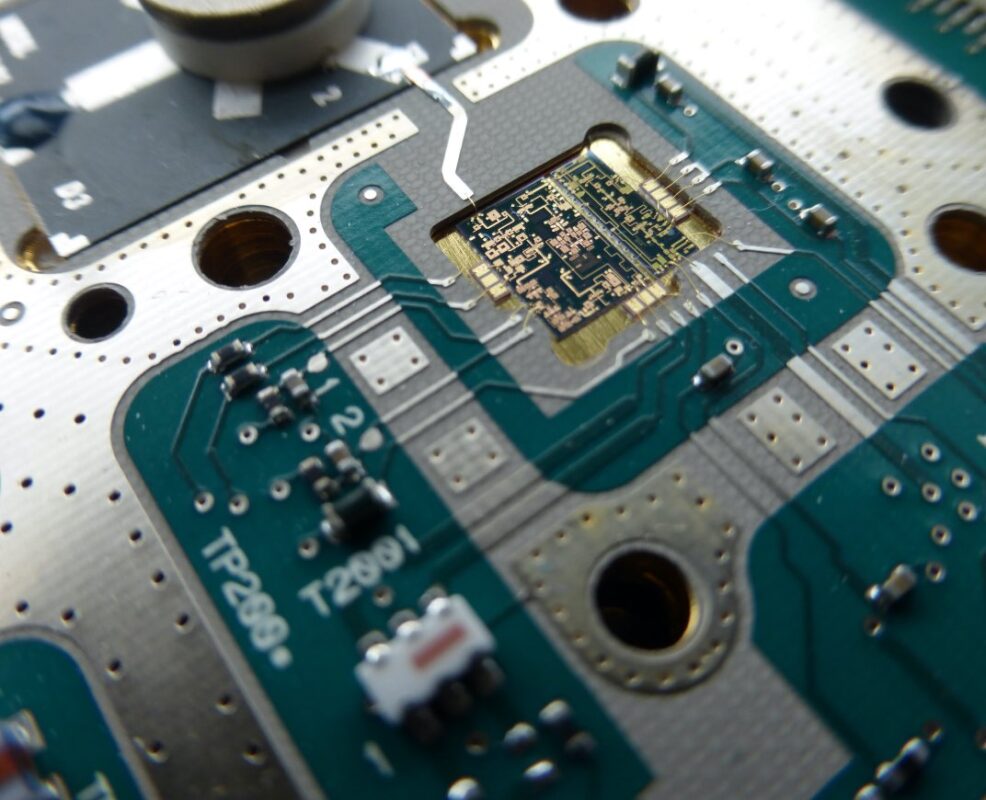

Air cavity package

Filtronic mixes GaAs, GaN and Silicon die in a single package offering unprecedented integration and system cost savings. To meet increasing demands for integration and cost reduction, Filtronic has developed a range of proprietary MMICs which are packaged in miniature surface mount multi chip modules enabling manufacture in mass SMT lines.

Supply chain resilience

Filtronic has a well-established global supply chain with strong supplier partnerships, and our buying power is increased by leveraging demand from multiple clients, which can result in significant BoM cost reduction. Our supplier partnerships include MMIC foundry and semiconductor vendors.

Screening

As part of the product design and microelectronic manufacture process Filtronic offer a comprehensive range of screening services. Filtronic has a range of in-house thermal HASS (Highly Accelerated Stress Screening) chambers which provide rapid temperature cycling of up to 60°C/Min ramp rate for screening out latent defects.

Dual sourcing

At Filtronic we have the capacity, experience and the expertise to design and manufacture high performance RF products at Microwave and mmWave. We are equally comfortable manufacturing to a customer’s design, as we are designing and manufacturing our own high-performance products. Alternatively, we love working with our clients, fusing their core competencies with ours to optimise their original design.

Featured products

Morpheus II

Morpheus X2

Cerus

Related media

Popular news, articles and white papers

- Pushing the boundaries in LEO applications – Filtronic expands presence in satellite communications market

- Filtronic cements position in LEO market with a new follow-on contract for Cerus 32

- Filtronic awarded £4.5 million contract with BAE Systems

- Filtronic wins a new radar contract from Defence Prime

- Filtronic strengthens its position within the E-band low Earth orbit market with second-generation Cerus 32 power module

- Filtronic releases highest power (>20W), commercially available E-band solid-state power amplifier (SSPA) on the market

- Filtronic wins “Manufacturer of the Year” at the prestigious annual Elektra Awards

- UK RF manufacturer contributes to ‘fibre-in-the-sky’ low Earth orbit network

- Hercules takes off in markets with a need for speed.

- Filtronic win major contract with European Space Agency’s ARTES programme.

- Filtronic secures second ESA project in six months.

- Scaling up semiconductor manufacturing for new-space applications

- RF specialist selected for Defence Technology Exploitation Programme.

- Filtronic strengthens sales partner network

- A close shave: 5G to the rescue

- Filtronic wins the Innovative Supplier Collaboration Award by Leonardo

- RF technology leader adds new service to portfolio

- Designing for the future

- Filtronic continues penetration of Low Earth Orbit market, with new contract win.

- The RF spectrum is not infinite – Ensuring RF spectrum sustainability amidst soaring demand